Channel News Asia. Making treasure out of trash

Envcares was featured in a CNA broadcast to show the extent of food wastes generated and Envcares valorization works.

SINGAPORE: Some businesses that generate large amounts of food waste have already started segregating and treating their waste, ahead of a law that will require them to do so from next year.

Among them is integrated resort Marina Bay Sands (MBS), which has close to 20 restaurant kitchens, banquets from Sands Expo and Convention Centre, and two employee dining rooms that serve up to about 15,000 meals a day.

To make better use of such waste, food scraps are recycled using five on-site digesters instead of being dumped in the rubbish bin, said the company’s sustainability manager Yeh Wei Xuan.

The digesters, which can break down up to six tonnes of food waste a day, produce non-potable water that is then disposed of responsibly, Ms Yeh said. The capacity of the digesters has been gradually increased since they were introduced in 2013, she added.

CONVERTING FOOD WASTE INTO OTHER SUBSTANCES

Since 2013, MBS has diverted about 7.8 million kg of food waste away from the landfill, Ms Yeh noted.

“If not for these waste digesters, we will have to engage contractors to haul off waste off-site to be incinerated,” she said.

The five machines are located centrally so that they remain accessible to both the hotel and shops.

The company uses a “fully circular” processing technology to process food waste into high calorific substrate that can be used for various purposes, Ms Yeh added.

It converts food waste into dry compost, which can be used as fertiliser or animal feed.

The integrated resort also uses food tracking technology to help chefs manage, monitor and reduce food waste, said Ms Yeh.

Its efforts come ahead of a law that will take effect next year.

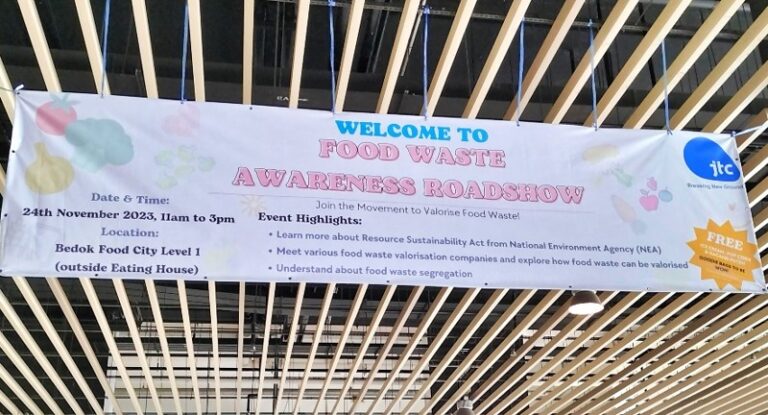

It will make it mandatory for the owners and operators of commercial and industrial premises, where large amounts of food waste are generated, to segregate their food waste for treatment. Such premises include large hotels and malls, and large industrial developments housing food manufacturers or food caterers.

OFF-SITE TREATMENT

To give businesses flexibility to pursue different ways of managing their food waste, the Sustainability and the Environment Ministry also allows for off-site treatment.

One food recycling plant in Tuas, Envcares, sees an average of 100 tonnes of food waste a day.

This includes unsold and expired food like bread and canned drinks.

“(The items) come from big food manufacturers, and they are all MNCs (multi-national corporations). These are the by-products from their manufacturing stream,” said the firm’s business development director Ong Gin Keat.

The firm has seen a “good increase” over the years and projects a year-on-year increase of about 5 to 10 per cent, he said.

Envcares processes the waste into various components.

For instance, the company crushes cans and extracts the liquid. This liquid will then be mixed to create compost, which will be sold to landscaping companies, vegetable farms and nurseries.

Aluminium can also be extracted and sold to scrap merchants who will sell it to steel recycling companies, said Mr Ong.

Expired bread is also put into good use – it is exported as insect feed instead of being tossed into landfills.

SUSTAINABILITY IS FOR ALL

Sustainability is for everybody, said Mr Ong, adding that food manufacturers have to play their part.

“The first thing is to reduce waste. We have very limited land, and of course we want to maximise the resources that are here,” he said.

As part of the nation’s bid towards zero waste, the government has built an integrated liquid and solid treatment plant at Tuas, which can treat up to 400 tonnes of food waste per day.

Singapore’s Zero Waste Masterplan aims to reduce waste-to-landfill per capita per day by 30 per cent by 2030, with a 20 per cent reduction in waste-to-landfill per capita per day by 2026 under the Singapore Green Plan 2030.

Targets are set with plans of extending the lifespan of Singapore’s only landfill beyond 2035.